King Training Innovations

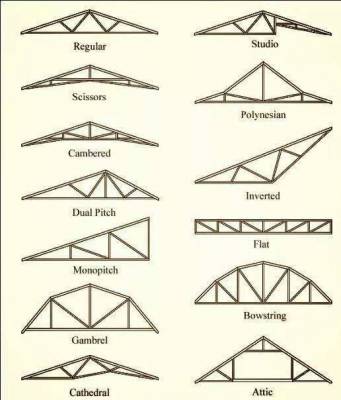

Knowing and being familiar with building construction is a great thing. If you know how its put together, it helps to understand how fire will effect it and how it comes down. Remeber to get back to the basics. Without general basic fire fighting knowledge and skills you really dont have much Get out and train. Below is a good picture that shows the many types of trusses out in the field. Remeber with trusses, if one part fails, the whole thing fails. Beware of light weight construction and how to recognize it. Stay safe.

Tactical Ventilation – The “Where” Continues. Let’s Go Vertical!

The “WHERE” Continues. Let’s Go Vertical

As we explore the different structure types and sizes as they relate to ventilation needs, we must now discuss the benefits and risks associated with vertical ventilation. For those of us that are directionally challenged that’s roof venting. Rooftop ventilation has come under attack in the last 10 years.

Those attacks have centered on safety of the roof vent team. Let’s face it, functioning on a roof of a structure that is on fire is inherently dangerous but it has proven time and again to be effective and necessary in various fire scenarios.

Those situations that I have found vertical ventilation to be necessary revolve around allowing the nozzle team to make their way to the seat of the fire, controlling fire spread, and most importantly preventing a major build-up of heat and flammable byproducts on the floor(s) above the fire.

In order to accomplish this goal in a timely fashion, we must have adequate personnel on scene. Let’s face it, it isn’t the easiest job in the fire service! Education and experience are the keys to accomplishing this task.

Here are the key elements you MUST understand:

Truck Company Positioning – Knowing Your District

In my previous article we touched on the importance of positioning the ladder truck. In this article we will explore more of the foundation for optimizing your position. One important key to any truck company is knowing your district. I cannot overstate the importance of this knowledge. Knowing your district gives you the keys to direction of travel, hydrants (you may ask why hydrant location is important, I will get to that shortly), overhead wires, type of structures by address, exposure potential and other apparatus. All of these items need to be considered in your positioning plan. Each one affects the ability to place the apparatus in the most advantageous location to accomplish your tasks.

The Keys to Your Response

Let’s break down the district knowledge keys. First you’re direction of travel. Knowing what direction you will be approaching the incident from tells you traffic patterns, ability to maneuver, other apparatus travel direction and the side of the structure you will have the best access.

Having this bit of knowledge sets the stage for good placement. If your knowledge tells you that two engine companies will arrive prior to you, and come from the opposite direction of your travel, it may be wise to let them know how you are entering to avoid being blocked out. They may very well expect you to come in from behind them and pull past the address. That two second radio message may save you hours of headaches.

Hydrants and the Engine Co

Hydrants, you ask why would I need to know about hydrants? Take it from experience, if you know the direction the engine is laying out from or to, you can make adjustments in how and in what order it is best to arrive. In my world we were an engine and truck house fortunately we had captains that understood the importance of equipment positioning.

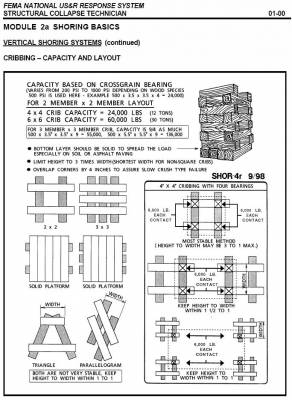

The following is some good info from FEMA on Cribbing. Get out out and get your hands on your cribbing. Set up basic crib towers and discuss various types of situations where you may need to think outside the box.

4 Steps To Simple Saw Maintenance

Maintaining our equipment so it performs safely and effectively as well as reliably is one our most important jobs. There is simply no excuse for taking a saw off the rig when needed and discovering that you cannot get it started or that the blade needed to be replaced from previous use and was not.

Some of the work included in properly maintaining your saw may require you to use the services of your department or district mechanic or repair shop but the simple steps below can be taken care of by a firefighter in house.

#1 – Fuel Mix

A two-cycle motor requires a fuel and two-cycle oil mix. If you run straight gas in a two-cycle motor prepare yourself for an impending disaster.

That being said, we must also keep in mind that the fuel/oil mix must be in the correct ratio for the particular manufacturer of saw that we are using. Some common ratios are 32:1, 40:1 and 50:1. The gas can you use to store your mix in should also be clearly labeled as to what is inside. Or, label it with the name of the particular saw that it is to be used for. It is also helpful to label the saw itself somewhere with what mixture is appropriate for that particular saw.

When fueling your saw, give the can a good shake before pouring gas into the saw. Over time, oil and gasoline can separate. Giving it a good shake prior to refueling will ensure a proper mixture makes it into the tank.